PCB Depanelling Machine

Series 4646

COMBINED SHANK AND / OR DISC - CUTTING TECHNOLOGY

ONE MODULAR CELL – VARIOUS FEEDING OPTIONS

LOW INVEST AUTOMATION

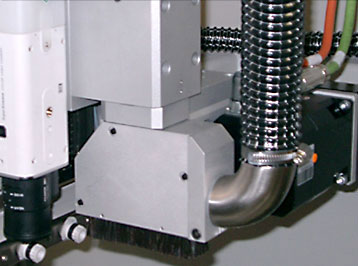

Pic.: SAT 4646 D, with V-CUT PRO Saw-Unit, Shutttle Feeder,

Barcode-Reader, Camera

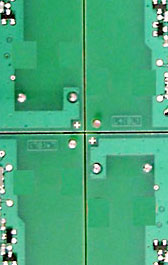

The Series 4646 depanelling platform alternatively detaches the assembled PCBs with shank tools or rotating diamond-coated/sawtooth-profiled discs. Both technologies can be combined in one spindle-unit to offer maximum flexibility with minimum set-up periods. The singulation process is performed from TOPSIDE, while the x/y- coordinates table pilots the assembled PCB. The PCB high mounting components are placed face downwards.

| |

|

| V-CUT PRO Saw-Unit

|

|

dust free depanelling

|

best lifetime price / performance ratio – while achieving industry-standard results

- meets all requirements of contemporary and future electronics components manufacturing

- rapid PCB-positioning – non-moving spindle-unit

- fast, highly stress- and dust-reduced depanelling of all PCB-layouts, either pre-scored, pre-routed or non-preworked solid panels

- maximum flexibility and yield, from batch size 1 to mass-production

|