PCB Marking System

Series 4646

COMBINED INKJET AND / OR LASER TECHNOLOGY

ONE MODULAR CELL - STAND-ALONE OR

IN-LINE OPERATION

LOW INVEST AUTOMATION

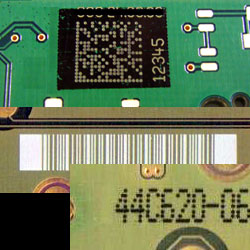

The Series 4646 PCB marking-system labels printed circuit boards of different surface colorizations with standard code-formats, such as barcode, 2D matrix codes or other imprints. Both marking technologies can be integrated as one combined device with subsequent marking-steps or applied individually. The marking process is performed from TOPSIDE, while the x/y- coordinates table pilots the flying PCB.

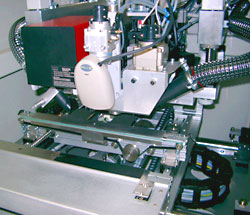

(Pic. INM 4646 IL with combined 0-90° INKJET / LASER-unit, CCD-camera, code-reader and loader / unloader for batch-processing).

- best lifetime price / performance ratio – while covering all contemporary and future marking requirements

- INKJET for spraying of colored base segment, CO2 laser for creation of barcode or 2D-code

- Teach-in CCD-camera with positioning correction and code-reader for immediate result verification

- linear-motor drives

Technical specifications

Machine

|

|

|

W x D x H

|

1000 x 1350 x 1750 mm

|

|

Working height

|

930 – 1050 mm

|

|

Weight

|

ca. 700 kg

|

|

Current

|

230 V / 50/60 Hz / 16 A

|

|

Compressed air

|

0,6 mPa (6bar), oilfree

|

|

Color

|

RAL 9002 / customer specific

|

|

|

|

Work space

|

|

|

Standard panelsize

|

460 x 460 mm

|

|

Mounting height top side:

|

max. 15 mm

|

|

bottom side:

|

max. 45 mm or customer specific

|

|

|

|

PCB fixation

|

|

|

|

|

|

With pins in PCB tool holes, edge clamping and supporting pins in unpopulated areas, if required in combination with vacuum pins. Flexible workflow direction.

|

Accuracy

|

|

Positioning

|

± 0,01 mm

|

|

Repeatability

|

± 0,015 mm

|

|

|

|

Dust extraction

|

|

|

External fume/dust vacuum unit

|

|

|

|

Noise level

|

|

|

Operating noise

|

59 db (A)

|

|

für Scheibenwerkzeuge

|

200 mm / sec.

|

|

|

|

System

|

|

- IPC-control DIN-language

- Path control

- Windows® user interface (WYSYWIG)

- Ethernet network interface, traceability

- Conveyor interface SMEMA

- Remote service

- DIN 66025 program-converter

|

|

|

|

Ink-Jet

|

|

Creation of Bar -, 2-D Matrix Codes, Logosand Graphics Markable lines

|

up to 4

|

|

Characters per sec. / line

|

up to 2133

|

|

Fonts

|

5x5, 7x5, 9x6, 12x8, 16x11, 19x14, 24x17

|

|

Character height

|

2 – 10 mm

|

|

Object proximity

|

9 mm

|

|

Statusindicator

|

visual

|

|

Jet unit rinsing

|

automated

|

|

External text entry

|

|

|

Swivel Jet unit 0 – 90°

|

|

|

Maintenance monitoring

|

|

|

Integrated text memory

|

|

|

|

|

Laser

|

|

|

CO2 source

|

10 W / 25 W

|

|

Operating area

|

110 x 110 mm

|

|

Spotsize 1 / e2

|

290 μm

|

|

Focal distance

|

190 ±3 mm

|

|

Marking speed

|

225 characters /sec.

|

|

|

|

Options

|

|

|

YAG Laser

|

8 / 10 W

|

|

Front loading shuttle in/out

|

|

|

Loader/Unloader/Conveyors

|

|

|

Z-axis stroke 60 mm

|

|

|

|

CE, ESD, EMC, accident prevention

|

|

The machine meets viable rating of local safety

|

|

|

Operating stand-by capability

|

|

|

> 98%

|

|

|

|

Machine qualifying references

|

|

|

|

|

|